-40%

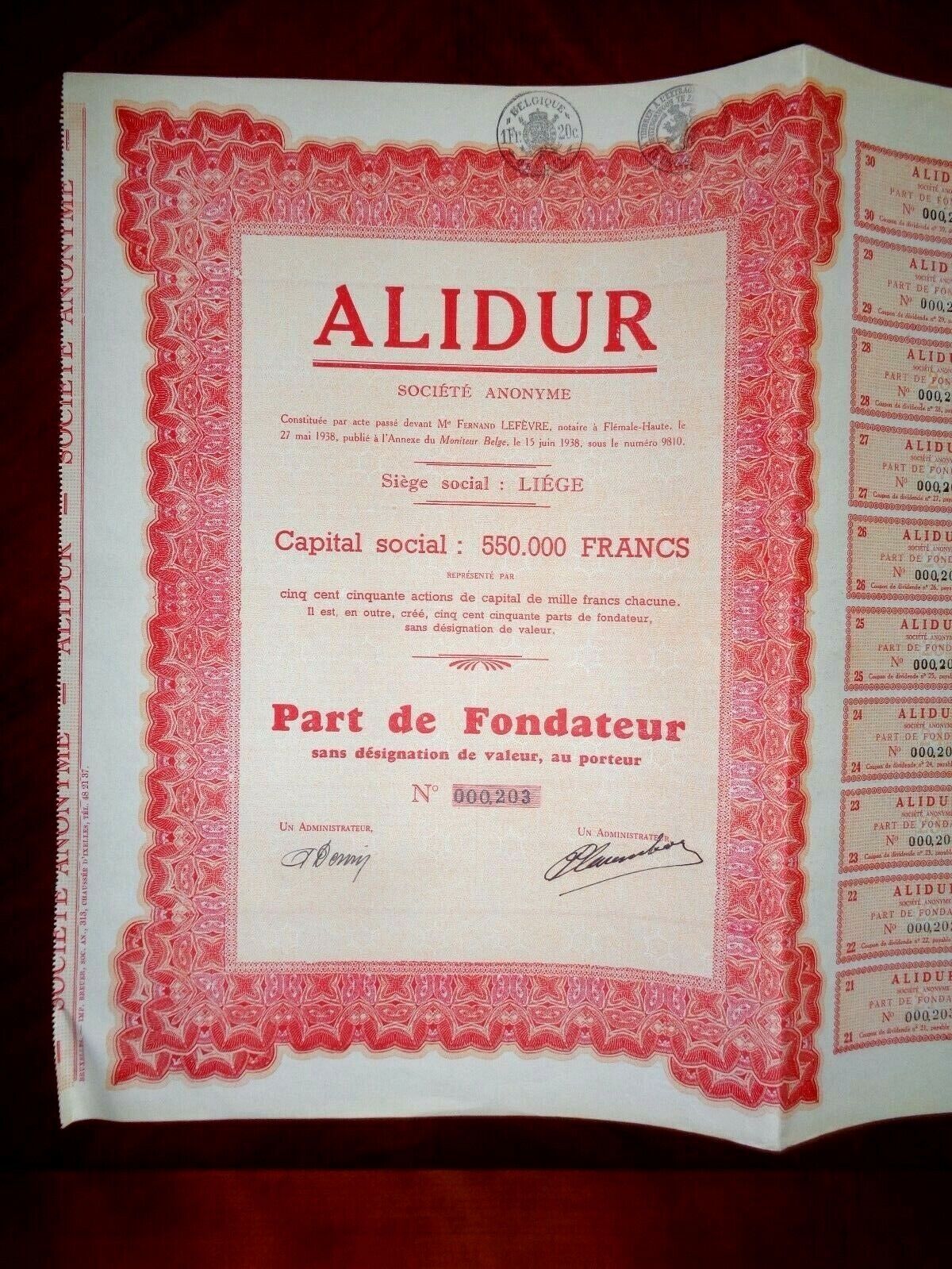

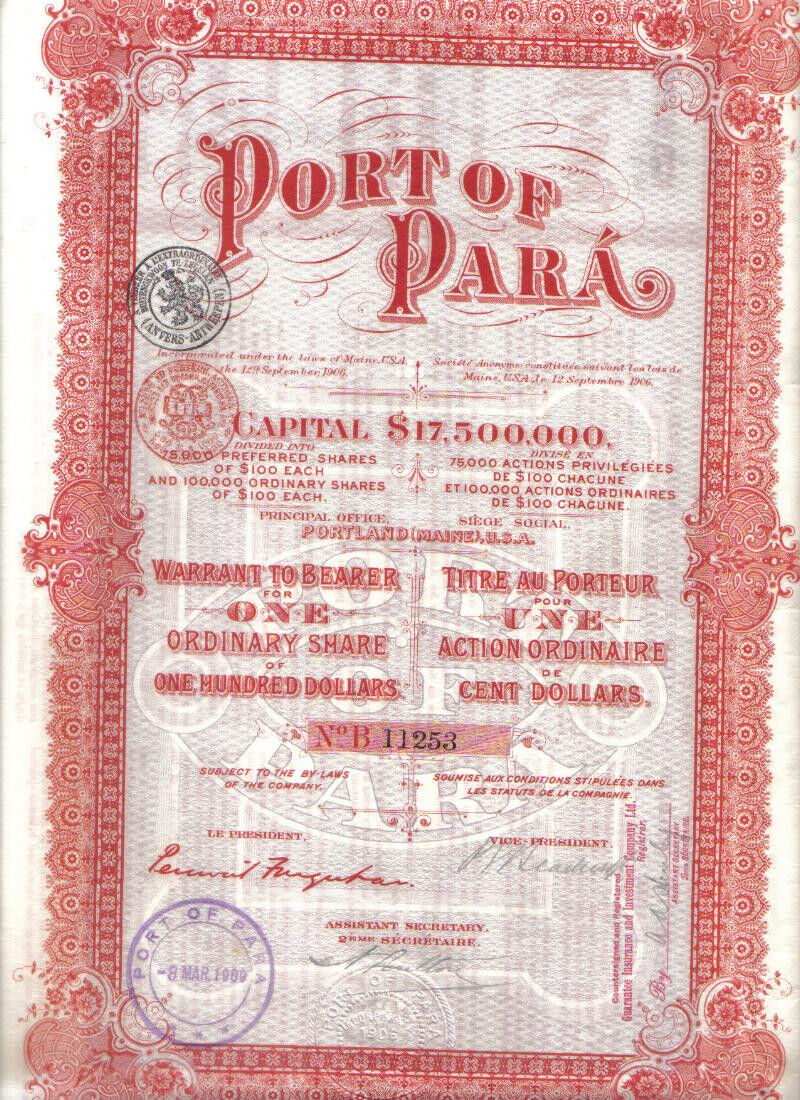

ALIDUR SA, Belgium Share certificate 1938

$ 3.43

- Description

- Size Guide

Description

One bearer share certificate (Part de Fondateur) of "ALIDUR" SA Liège ,Belgium 1938, without nominal value.Capital 550.000 francs.Condition (opinion):Very Fine (VF )

.Founded 1938.

Manufacture of light alloys.

Aluminium Foundry

Printer:Imp.Breuer SA ,Bruxelles.Uncancelled ,all 30 coupons remain uncut.

Founders:Ferdinand Clarenbaux et Forir, Mathieu Forir

Start business in Herstal,near Germany just before II WW and close to important gun industries in Herstal (still today)

(Fonderie aluminium.Fabrication d´alliages légers). There is a posibility,to be verified, the ALIDUR company was related with arms and military industrie.See below for related information from the web.

--------------------------------------------------------------------------------------------------------------

Postage, including packing material, handling fees : Europe: USD 4.10 / USA $ 4.90. Rest of the World: USD 5.50

FREE of postage for any other additional banknote , stocks & bonds or other items

Only one shipping charge per shipment (the highest one) no matter how many items you buy (combined shipping).

Guaranteed genuine -

.

One

month

return

policy

for

the

banknotes (retail sales).

Customers are invited to combine purchases to save postage.

Full refund policy ,including shipping cost,guaranteed in case of lost or theft after the completion of the complaint with Spanish Correos for the registered letters (normally purchases above $ 40.00).

As we have more than one identical item ,the serial number may differ from those shown in the picture which is for reference only.

For some destinations and purchases below .00 customers may be requested for a small extra shipping payment in order to register the shipment with tracking number.

------------------------------------------------------------------------------

Banknote Grading

UNC

AU

EF

VF

F

VG

G

Fair

Poor

Uncirculated

About Uncirculated

Extremely Fine

Very Fine

Fine

Very Good

Good

Fair

Poor

Edges

no counting marks

light counting folds OR...

light counting folds

corners are not fully rounded

much handling on edges

rounded edges

Folds

no folds

...OR one light fold through center

max. three light folds or one strong crease

several horizontal and vertical folds

many folds and creases

Paper

color

paper is clean with bright colors

paper may have minimal dirt or some color smudging, but still crisp

paper is not excessively dirty, but may have some softness

paper may be dirty, discolored or stained

very dirty, discolored and with some writing

very dirty, discolorated, with writing and some obscured portions

very dirty, discolored, with writing and obscured portions

Tears

no tears

no tears into the border

minor tears in the border, but out of design

tears into the design

Holes

no holes

no center hole, but staple hole usual

center hole and staple hole

Integrity

no pieces missing

no large pieces missing

piece missing

piece missing or tape holding pieces together

See some related information from the web:

( to be verified)

The following characterizations were carried out on the polymers mentioned in the examples:

Characterization:

Melt Flow Index (M.F.I.)

The M.F.I. of the fluorinated polymers is measured according to the ASTM 3275-89 method, at 275°C and with a weight of 2.16 kg.

Second melting temperature (T

mII

)

The T

mII

of the fluorinated polymers is determined by differential scanning calorimetry (DSC).

Permeability to water-vapor at 100°C

A metal plaque coated with a polymer layer is subjected to saturated water-vapor atmosphere at 100°C. The time at which blisters appear on the coating surface is measured.

Peeling force

The necessary force (N/mm) to separate the coating from the substrate is measured by a dynamometer.

Some illustrative Examples but not limitative of the present invention follow.

EXAMPLES

Preparation of the specimens

A carbon steel plaque of 100 mm x 100 mm with a thickness of 3 mm is sandblasted with sand of the type 16 mesh-sized brown red Corindone

ALIDUR

®, obtaining a roughness of about 7 micron.

Subsequently the plaque is heated in an oven at 275°C for 40 minutes and then extracted from the oven and earthed. The coating material is immediately sprayed thereon under the form of dry powder using a gun produced by the Swiss company GEMA, mod. 701/6, which electrostatically charges said powder with 40 kV voltage.

The plaque, after having been homogeneously coated with a first powder layer, is put again in the oven at the same temperature for 10 minutes.

Once the plaque has been extracted from the oven, other powder layers can be applied thereon, equal to or different from that of the first layer, repeating the above spraying and heating procedures in the oven.

More plaques are prepared, some of which are exposed to saturated water-vapor at 100°C (1 atm). Then the peeling force is measured on the plaques exposed to saturated water-vapor and on those not exposed.

<div style="text-align:center"><a style="text-decoration:none" href="http://mostpopular.sellathon.com/?id=AC1061546"><img src="http://www.sellathon.com/Resources/Images/countercredit.gif" border="0"></a></div>

Your browser does not support JavaScript. To view this page, enable JavaScript if it is disabled or upgrade your browser.